Inorganic-Organic hybrid materials

Formation behaviour of domains in hybrid polymers

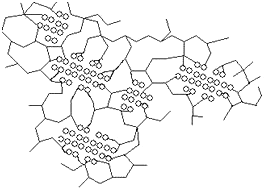

Hybrid polymers, also called nano composites, are described as macromolecular substances build from organic and inorganic domains, which are in the ideal case chemically bonded.

Polymers consisting of an inorganic backbone with organic or organometallic side chains are called inorganic organic hybrid polymers (IOP), while polymers consisting of an organic backbone with inorganic side chains or groups are called organic inorganic hybrid polymers (OIP).

The inorganic domains will affect abilities like thermal resistance, fire resistance, resistance to radiation, biological stability and electrical conductivity. The organic domains will affect solubility, flexibility, hydrophobicity and other surface related abilities.

One of the most common methods for the synthesis of hybrid polymers is the sol-gel process. An inorganic network is built by controlled hydrolysis and condensation of organically modified metal oxides, in this case silicon. This inorganic network can be further modified.

One of the assets of sol-gel coating materials when compared with other inorganic coatings is their ability to be applied wet like common coating materials. The coating will switch from liquid sol state to sol-gel state.

Sol-gel coatings are already used for

- Anti-reflective coatings for glasses

- Scratch resistant coatings for polycarbonate and windscreens

- Corrosion protection of metal substrates

- Easy to clean and anti-fingerprint coatings

- High temperature stable coatings for metal substrates

- Antimicrobial coatings