DPE dispersions

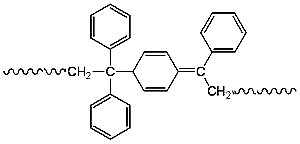

The water-based Controlled Radical Polymerization (CRP) has been one of the fastest growing fields of interest in polymer research for the past decades. "Nitroxide mediated polymerization" (NMP), "atomic transfer radical polymerization" (ATRP) and "reversible addition fragmentation chain transfer" (RAFT) are the most common methods used today. Besides these, a method was developed using 1,1-Diphenylethylene (DPE).

The synthesis of emulgator-, metall-, additive- and solvent free waterborne dispersions is possible with the DPE-method.

The mechanism

With the DPE-method, block copolymers are synthesized in a two step process. In the first step an oligomeric, hydrophilic precursor is synthesized from hydrophilic monomers (like acrylates, methacrylates and methylmethacrylates), 1,1-Diphenylethylene and an peroxodisulfate initiator.

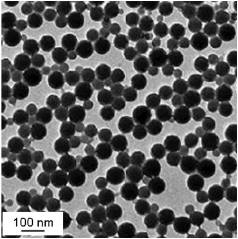

This precursor is the stabilizing species in the 2nd polymerization step. Here, non-polar monomers ((meth)acrylates, styrene etc.) are coupled to this hydrophilic segment in an addition-fragmentation mechanism. The amphiphilic block copolymers formed in this way immediately aggregate to form micelles, which grow from 10 nm in diameter to a size of 50-150 nm after further monomer addition.

Dispersions of unconventional block copolymers with core-shell structures can be produced using this process.

They exhibit some interesting properties in terms of application technology:

- They show film-forming behavior well below the glass transition temperature and can be used as solvent-free coating and adhesive systems.

- Their functionalized dispersion particles can be locally addressed on galvanized substrates and thus achieve a corrosion-inhibiting effect.

- Due to their special micellar structure, both the nucleation and the particle growth of calcium carbonate and barium sulphate nanoparticles can be controlled; various particle morphologies and hollow mineral spheres can be produced.