Materials Interfaces, Corrosion Science, and Sustainable Thin Film Engineering

The main scientific focus of the Adhesion and Corrosion Science group is to achieve a fundamental understanding of structures, forces, and reactions at materials interfaces. The control of adhesion and corrosion reactions plays a major role in durability and functional properties. Mainly, we focus on model materials surfaces and interfaces (e.g., single crystals, self-assembled monolayers), which allow for the application of sophisticated analytical methods. Related new concepts are transferred to the other research groups of the TMC. Thereby, this group is focused on interdisciplinary topics.

Analysis of Interfacial Forces

Interfacial forces under controlled environmental conditions are studied based on Single Molecule Force Spectroscopy, Chemical Force Microscopy and Colloidal Probe Technique Spectroscopy. Such AFM techniques allow for a quantification of interfacial and contact forces of organic molecules, macromolecules, and particles.

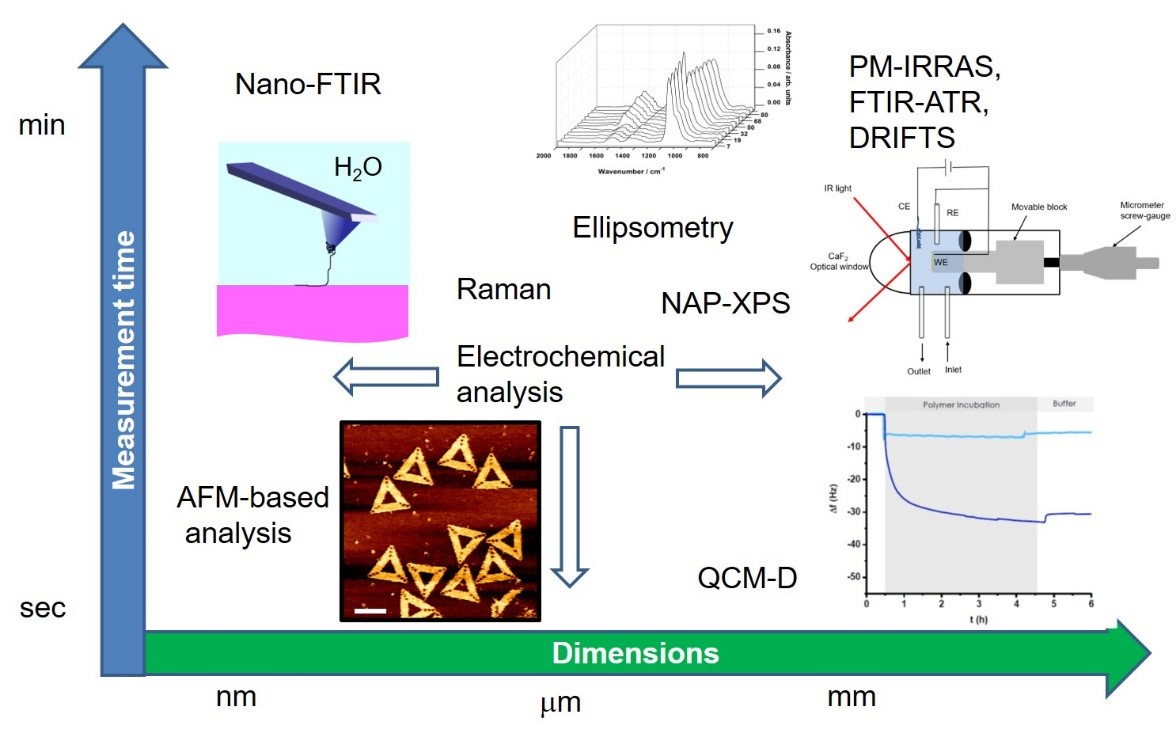

Interface Electrochemistry and Spectroelectrochemistry

Kelvin Probe methods on the microscopic and nanoscopic level, as well as cyclic voltammetry and electrochemical impedance spectroscopy, are methods that are applied and adapted to advanced engineering and functional materials.

FTIR and Raman Spectroscopy are coupled with the control of the electrode potential and the analysis of interfacial current densities. Backside measurements, diffuse reflectance, as well as grazing incidence and attenuated total reflectance methods have been established for various applications.

Molecular Surface Chemistry

Molecular surface chemistry comprises self-assembly processes of organosilanes, thiols, phosphonates, and carboxylates, electrografting of diazonium salts, and CVD of organosilanes. Thereby, functional materials, surfaces, and modified particles for additive manufacturing are created.

In-situ Interface Spectroscopy and Nano-FTIR Spectroscopy

In-situ and operando spectroscopic approaches based on FTIR, Raman, XPS, and ICP-OES analysis are developed for the study of interface and corrosion reactions under ambient and corrosive conditions. Recently, a Near-Ambient Pressure (NAP)-XPS and a Nano-FTIR system were installed to allow for the analysis of ultra-thin adsorbates and single macromolecules under controlled environmental conditions.

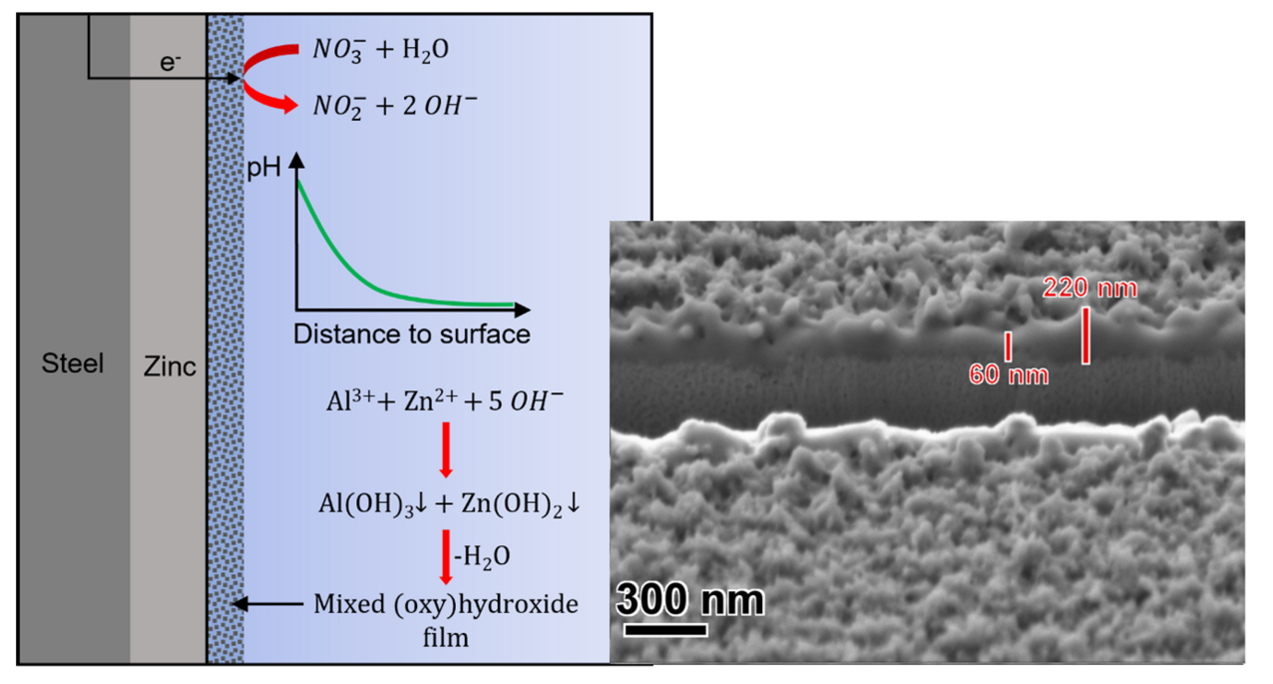

Corrosion of Metal Alloys and Polymer/Metal Interfaces

Corrosion studies consider both highly corrosion-resistant alloys and bioresorbable metal alloys for medical applications. Advanced alloys are synthesized via additive manufacturing in collaboration with dedicated research groups. Thin metal films are deposited by magnetron sputtering as a dry technology. A system for combinatorial thin-film deposition and analysis enables the development of functional thin-film compositions. Finally, corrosion studies consider interfaces in composite materials. In such cases, the analysis of polymer/metal and polymer/fiber interfaces is based on special interface analytical techniques such as the Kelvin Probe or confocal Raman spectroscopy.

Sustainable Surface and Thin Film Technologies

The electrification of surface engineering based on plasma surface chemistry and electrochemical surface engineering allows for the sustainable deposition of thin functional films on metals and polymers. Moreover, the adjustment of functional properties of surfaces by the adsorption of self-organised organic monolayers or thin films in the range of a few nanometers leads to the protection of valuable resources. In general, we strive to take a comprehensive view of thin-film chemistry and process technology to promote the transfer of fundamental knowledge into industrial applications.