Polymeric adhesive layers in maritime environment

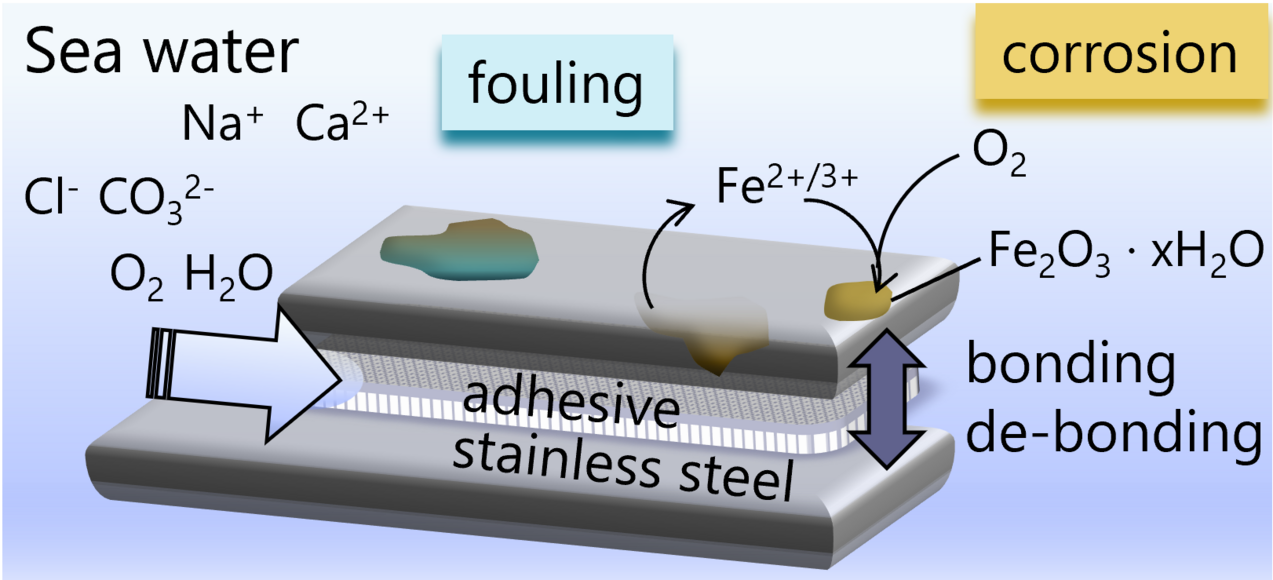

Bonding is the preferred joining method for fiber composites and is well established in ship building, whereas welding remains predominant for steel structures in contact with seawater.

The research group focuses on replacing energy- and cost-intensive welding of metal oxides in marine environments by adhesive bonding processes, while at the same time enabling repeated use of the joint parts, which requires residue-free debonding on a molecular scale. Longtime seawater exposure, however, promotes water uptake of the adhesive, while biofouling and corrosion on material side further challenge the transition.

The working group analyzes the adhesive/metal oxide interface during different stages of bonding and de-bonding using simulations and combined spectroscopic, electrochemical, and microscopic methods, while also evaluating adhesion promoters. The studies advance the mechanistic understanding and optimization of adhesion and de-adhesion processes.

Selected publications:

A contribution to the mechanistic understanding of the improvement of the delamination resistance of adhesives on steel by grit-blasting

L. Ruhm, V. Neßlinger, R. Becker, G. Meschut, G. Grundmeier

International Journal of Adhesion and Adhesives (2025), 143, 104147