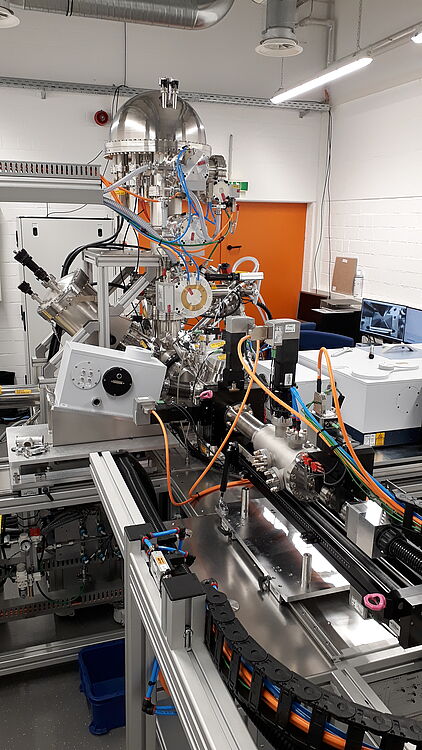

Paderborn Integrated Analysis-Near Ambient Pressure: PIANAP

This experimental setup combines photoelectron spectroscopy (PES) in the x-ray range (XPS) and ultra-violet range (UPS) with infrared spectroscopy (FT-IRRAS). The setup allows the surface characterization of materials in a pressure range of up to 20 mbar. The Phoibos analyser from SPECS is combined with a µ-focus AlKa monochromatized X-ray source so that it is possible to perform XPS for pressures between UHV up to about 10 mbar, and UPS up to about 2-5 mbar.

Features of the setup

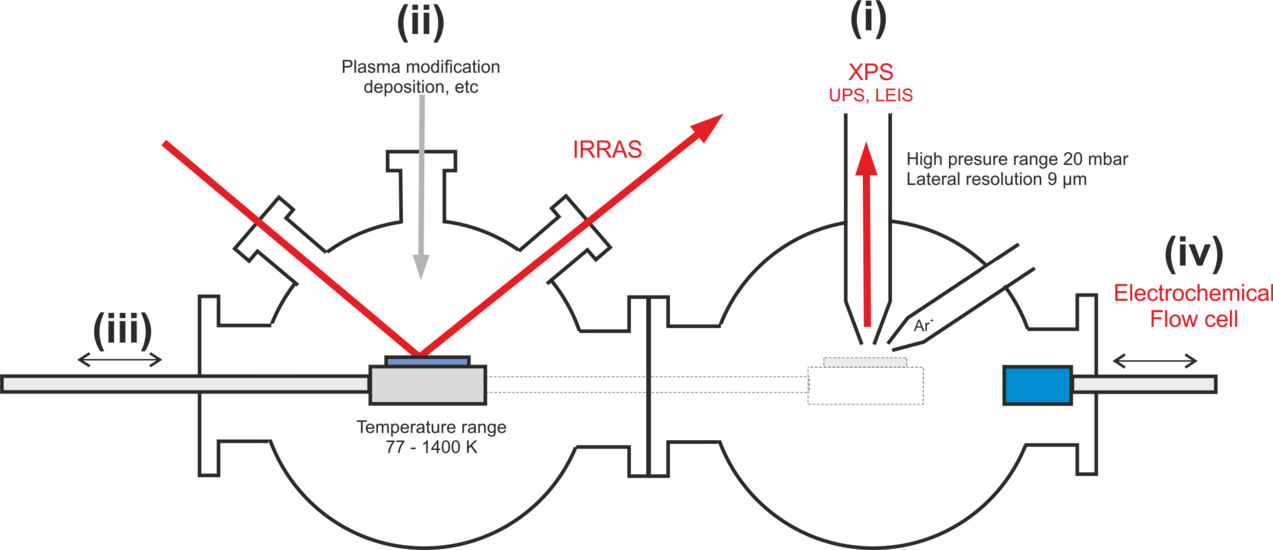

The schema below shows schematically the different components of the setup, which is divided into two interconnected chambers, one for PES (i) and one for IRRAS (ii). The samples are mounted on a manipulator stage (iii) that can be cooled down to liquid nitrogen temperature and heated up to 1000°C with the use of a NIR laser. The samples can be transferred between the two measurement stages keeping temperature and pressure conditions constant. At the “IR position” IRRAS characterization can be done “in-operando” conditions during all possible surface modification techniques, such as deposition, plasma, heating, etc. The “XPS position” allows for “in-operando” XPS measurements that involve heating/cooling and exposure to gas, and in-situ measurements of samples treated at the IR position (sputtered, deposited, plasma treated samples…) under identical pressure conditions. Additionally, a third chamber (iv) is attached to the PES chamber; this chamber is dedicated to electrochemical (EC) processes. A EC cell can be introduced into this chamber, which is also connected to the PES chamber. The EC cell can be placed at the PES stage so that in operando measurements of the electrochemical processes at the surface of the electrodes can be performed by PES.