Enzymes as Architects

Formation of self-assembled, high-precision films and structures on surfaces over multiple length-scales and in various media is a great challenge. Conventional technologies are either highly complex and demanding or suffer from reduced flexibility and control. Enzymatic catalysis is highly acclaimed in many areas, due to its unrivaled specificity, adaptability, and efficiency. Its existence is one of the main reasons behind the sophisticated capabilities of natural materials. From this point of view, application of enzymes as nano-scaled architects of synthetic and biomimetic materials easily appears as a potent scenario for the future of materials science.

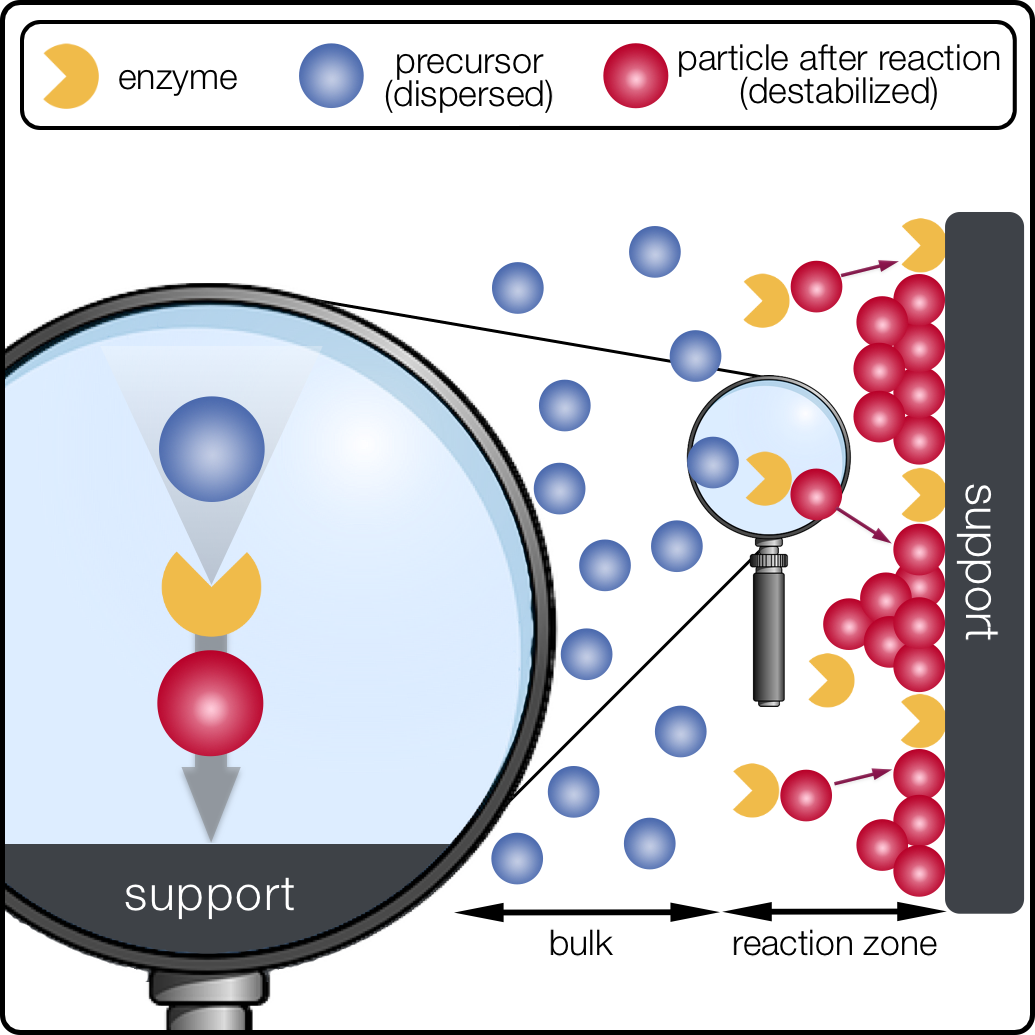

From this rationale, our novel technology for material design and nano structuring on surfaces is developed – the enzyme-mediated addressing. Key aspect of this technology is an enzymatic reaction in direct proximity to the support surface, which induces site-specific deposition of desired particles on the support. The size of the enzymatic reaction zone is tunable by variable enzyme immobilization techniques. Consequently, deposition patterns are fully flexible; from continuous coatings with defined film parameters to nano structures from single particles and everything in between.

This supreme specificity is however not the only advantage of the technology. Moreover, it stands out by high flexibility regarding many aspects, like compatibility of support and particle materials, as well as by the straightforward feasibility of the entire process. Depending on the desired material to be addressed, the technology can be utilized in different variations. In detail, the enzymatic reaction can either destabilize existing precursor-particles or mediate an in situ buildup of new particles from low molecular precursors. This, in combination with the manifold types of enzymes and immobilization techniques, generates a virtually unlimited toolbox for materials compatibility.

All this is achievable within an easily applicable and upscalable process, which is a key benefit of enzyme-mediated addressing in comparison to competing technologies, that enable similar specificity. The entire process is performed as two consecutive dip-coating steps without the necessity for complex and expensive devices. Moreover, though the specificity of a single enzyme is on the angstrom-level, it is retained even at high length scales.

The combined abilities of enzyme-mediated addressing render it a potent technology for surface modification and coating in many areas of industry. Most promising applications are certainly found, where high precision and uniformity of structures are crucial, like biomaterials for implantation or nanotechnological devices.